Prosthetic eyes are made of an acrylic plastic material called methyl methacrylate. It can be formed into any size and shape, it's durable, and is well-tolerated by the surrounding eye tissues. The prosthesis is made through the following series of steps:

|

|

1.

|

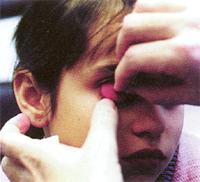

Sometimes the process begins by taking an impression of the eye socket to duplicate the exact nature of the space the prosthesis will fit into. The impression of the eye socket is used to make a wax model. Using the model, we determine the correct positioning of the iris (the colored part of the eye), the outer curvature, and the extent to which the eyelids will open. |

|

|

|

|

2.

|

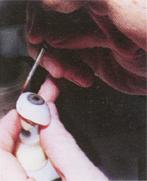

The iris is hand painted from direct observation of the unaffected eye. |

|

|

|

|

3.

|

The wax model is then used to prepare a master mold which is filled with acrylic plastic to create a cast of the prosthesis. |

|

|

|

|

4.

|

The prosthesis is further colorized and vessels are added to simulate a natural appearance. It is then covered with a clear plastic protective coating and is cured once more. |

|

|

|

|

5.

|

The prosthesis is now ready for a polishing to give it a perfectly smooth surface and wet-looking appearance. |

|

|

|

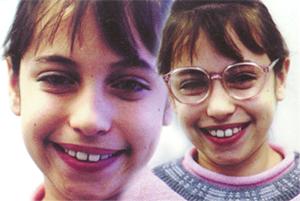

| Finally, the prosthesis is complete. Its appearance is deceivingly real, while the underside is an exact replica of the socket. It fits snugly and comfortably in place. |

|

|

|